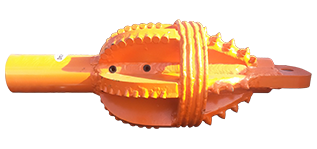

HDD PDC Reamers

©2013 Drillhead, Inc. HDD Tools and Horizontal Directional Drill Bits. All rights reserved. No re-use or distribution of any content.

Ditch Witch® is a registered trademark of The Charles Machine Works Inc.

Vermeer® is a registered trademark of Vermeer Manufacturing Company Inc.

American Augers® is a registered trademark of American Augers Inc.

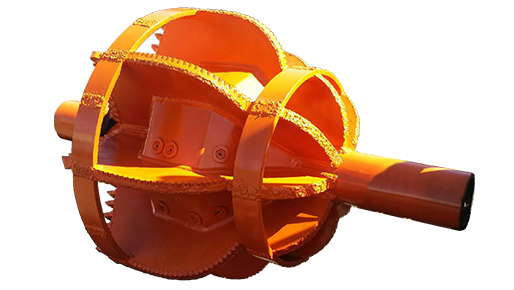

PDC REAMERS - PDC HOLE OPENERS

Available in all sizes and configurations.

• PDC REAMERS FOR ALL HDD DRILLS

• STANDARD AND CUSTOM PDC REAMERS AVAILABLE

• PDC REAMERS FOR ALL ROCK TYPES

• PUSH AND PULL REAMER DESIGNS

• FASTER DRILLING

• SMOOTHER RUNNING

• LONGER TOOL LIFE

• LOWER OVERALL COST TO OPERATE

• 4, 5, 6 AND 7 BLADE DESIGNS AVAILABLE

• CAN BE CUSTOM BUILT TO YOUR SPECS

• REBUILDABLE

ANY CONNECTION(S)

BOX, PIN, PULL TAB

OR SWIVEL AVAILABLE

CARBIDE TEETH AID

WHILE SWABBING

PDC CUTTERS (POLYCRYSTALLINE DIAMOND COMPACT)

-

•THE HARDEST MAN-MADE SUBSTANCE ON EARTH

-

•CUTS FASTER AND LASTS LONGER THAN CARBIDE

4, 5, 6 AND 7 BLADE OPTIONS

-

•MATCHED TO YOUR REQUIREMENTS

CHANGEABLE JETS ON MOST SIZES

• DRILLS FASTER

• LASTS LONGER

• REBUILDABLE

REBUILD SERVICE

OVERNIGHT SHIPPING AVAILABLE ON SMALLER SIZES

FOR ALL STYLES OF REAMERS,

FROM ALL MANUFACTURERS.

PDC REAMERS

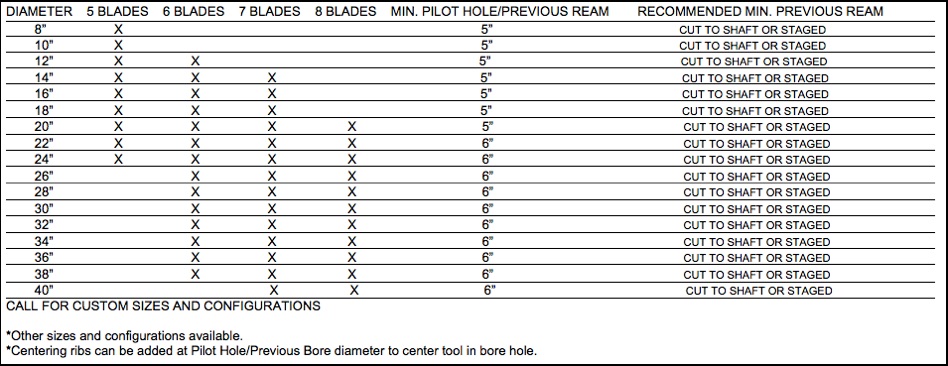

Popular PDC Reamer Sizes and Configurations

MANY POPULAR SIZES IN-STOCK, READY TO SHIP

FROM OUR MIDWEST AND NORTHWEST LOCATIONS

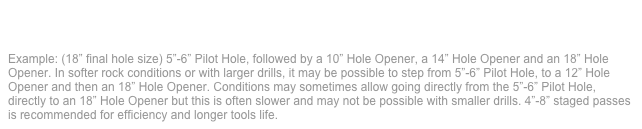

The newest technology in rock reaming is here. Fast, efficient and rugged.

HDD PDC REAMERS / HOLE OPENERS

PDC Rock Reamers offer many advantages!

In the right rock formations, a PDC hole opener / rock reamer will outperform and outlast a roller cone reamer. Faster, more efficient and longer lasting.

• 6” - 48”+ PDC reamer sizes available

• Any size PDC Hole Reamer available for any HDD drill

• Custom PDC reamers typically built within 3-5 business days

• Connection(s) available to fit any HDD drill rod or adapter

• 5, 6, 7 and 8 blade options

• American Made, built to last

• Fully customizable. We can build the exact PDC reamer you need

• Lower rebuild cost than roller cone reamers

Various 6"-48" Sizes in stock. Standard or Custom builds. Cut to the shaft, or

with carbide-covered centering ribs to cut from your pilot hole or

previous bore out to gauge.

COMPETITIVE PRICING UNBEATABLE QUALITY

42” 8-Blade Shown

with 4 1/2” IF Box X Box